Electrochemical Etching Silicon . Web we report the fabrication of nanoporous silicon (npsi) electrodes via electrochemical etching to form a porous si layer with controllable thickness and pore size. Reported silicon electrochemical etching (ece), which shows an etching rate faster than the dry etch. Varying the etching time and ethanolic hf concentration results in different surface morphologies, with various degrees of electrolyte access depending on the pore. Web the proposed model of electrochemical etching of silicon makes it possible to explain many of the. Web while conventional electrochemical etching is the most widespread approach used. Web electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Web for example, cozzi et al. Web here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by.

from www.researchgate.net

Web while conventional electrochemical etching is the most widespread approach used. Web for example, cozzi et al. Reported silicon electrochemical etching (ece), which shows an etching rate faster than the dry etch. Web electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Web here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by. Web the proposed model of electrochemical etching of silicon makes it possible to explain many of the. Web we report the fabrication of nanoporous silicon (npsi) electrodes via electrochemical etching to form a porous si layer with controllable thickness and pore size. Varying the etching time and ethanolic hf concentration results in different surface morphologies, with various degrees of electrolyte access depending on the pore.

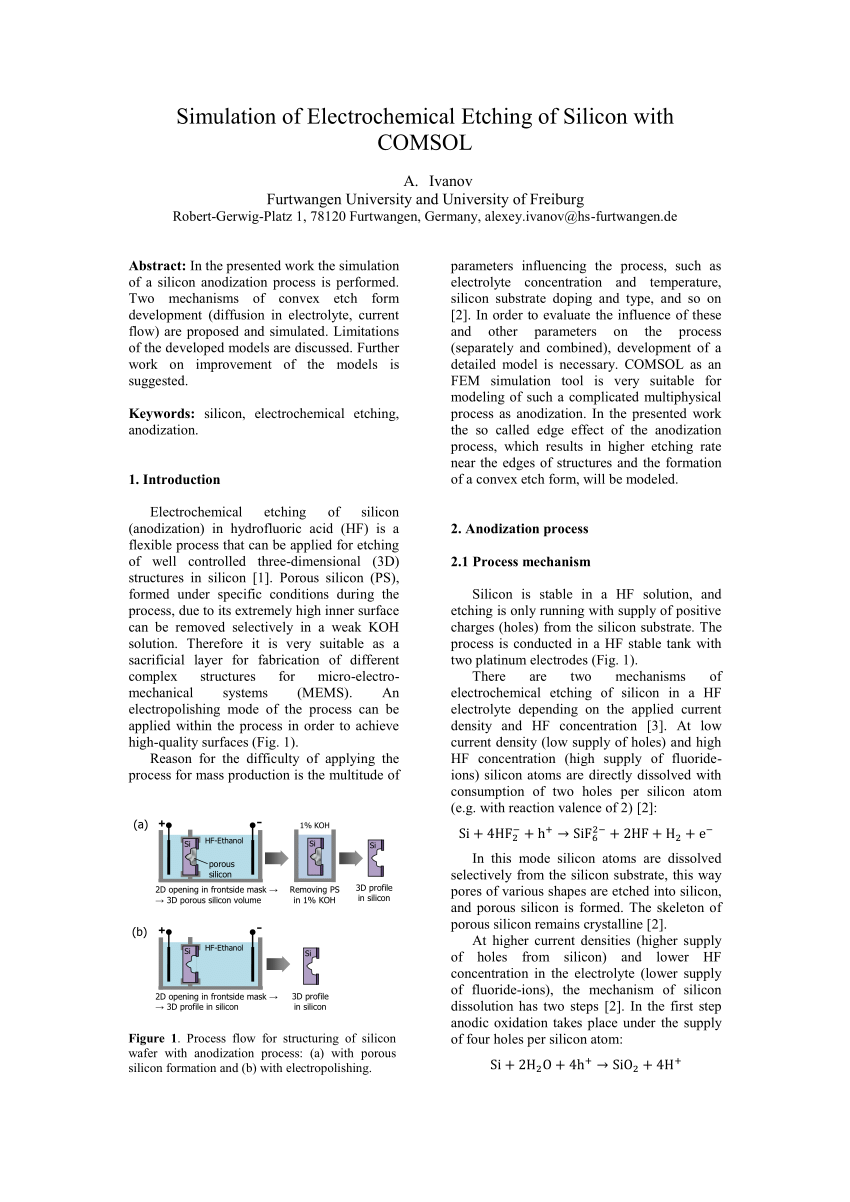

(PDF) Simulation of Electrochemical Etching of Silicon with COMSOL

Electrochemical Etching Silicon Web electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Web for example, cozzi et al. Varying the etching time and ethanolic hf concentration results in different surface morphologies, with various degrees of electrolyte access depending on the pore. Reported silicon electrochemical etching (ece), which shows an etching rate faster than the dry etch. Web while conventional electrochemical etching is the most widespread approach used. Web we report the fabrication of nanoporous silicon (npsi) electrodes via electrochemical etching to form a porous si layer with controllable thickness and pore size. Web the proposed model of electrochemical etching of silicon makes it possible to explain many of the. Web here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by. Web electrochemical etching is a method that requires an electric current to initiate the etching of silicon.

From www.researchgate.net

(PDF) Simulation of Electrochemical Etching of Silicon with COMSOL Electrochemical Etching Silicon Reported silicon electrochemical etching (ece), which shows an etching rate faster than the dry etch. Web electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Web for example, cozzi et al. Web here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by. Web we report the fabrication of. Electrochemical Etching Silicon.

From www.researchgate.net

The electrochemical etching process (A) and obtaining the electrical Electrochemical Etching Silicon Web electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Web the proposed model of electrochemical etching of silicon makes it possible to explain many of the. Web we report the fabrication of nanoporous silicon (npsi) electrodes via electrochemical etching to form a porous si layer with controllable thickness and pore size. Varying. Electrochemical Etching Silicon.

From opticalengineering.spiedigitallibrary.org

Fabrication of porous siliconbased silicononinsulator photonic Electrochemical Etching Silicon Web we report the fabrication of nanoporous silicon (npsi) electrodes via electrochemical etching to form a porous si layer with controllable thickness and pore size. Web while conventional electrochemical etching is the most widespread approach used. Reported silicon electrochemical etching (ece), which shows an etching rate faster than the dry etch. Web electrochemical etching is a method that requires an. Electrochemical Etching Silicon.

From www.researchgate.net

Electrochemical etching process. (a) At a beginning step. (b) At an Electrochemical Etching Silicon Web the proposed model of electrochemical etching of silicon makes it possible to explain many of the. Web here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by. Web for example, cozzi et al. Web we report the fabrication of nanoporous silicon (npsi) electrodes via electrochemical etching to form a porous si layer with controllable. Electrochemical Etching Silicon.

From www.researchgate.net

Schematic representation of the setup for electrochemical etching of Electrochemical Etching Silicon Web electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Web we report the fabrication of nanoporous silicon (npsi) electrodes via electrochemical etching to form a porous si layer with controllable thickness and pore size. Web here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by. Reported silicon. Electrochemical Etching Silicon.

From www.researchgate.net

(PDF) Silicon quantum dots prepared by electrochemical etching and Electrochemical Etching Silicon Web here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by. Web while conventional electrochemical etching is the most widespread approach used. Web for example, cozzi et al. Web the proposed model of electrochemical etching of silicon makes it possible to explain many of the. Reported silicon electrochemical etching (ece), which shows an etching rate. Electrochemical Etching Silicon.

From dokumen.tips

(PDF) Dynamic Simulation of Electrochemical Etching of Silicon Electrochemical Etching Silicon Web for example, cozzi et al. Web while conventional electrochemical etching is the most widespread approach used. Reported silicon electrochemical etching (ece), which shows an etching rate faster than the dry etch. Varying the etching time and ethanolic hf concentration results in different surface morphologies, with various degrees of electrolyte access depending on the pore. Web here, we propose an. Electrochemical Etching Silicon.

From pubs.acs.org

Deep Etching of Silicon Based on MetalAssisted Chemical Etching ACS Electrochemical Etching Silicon Web here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by. Web electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Web we report the fabrication of nanoporous silicon (npsi) electrodes via electrochemical etching to form a porous si layer with controllable thickness and pore size. Web the. Electrochemical Etching Silicon.

From www.researchgate.net

Basic schematic of electrochemical etching method Download Scientific Electrochemical Etching Silicon Web while conventional electrochemical etching is the most widespread approach used. Web here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by. Web for example, cozzi et al. Reported silicon electrochemical etching (ece), which shows an etching rate faster than the dry etch. Web we report the fabrication of nanoporous silicon (npsi) electrodes via electrochemical. Electrochemical Etching Silicon.

From link.springer.com

Electrochemical Etching Methods for Producing Porous Silicon SpringerLink Electrochemical Etching Silicon Reported silicon electrochemical etching (ece), which shows an etching rate faster than the dry etch. Web while conventional electrochemical etching is the most widespread approach used. Web electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Web for example, cozzi et al. Varying the etching time and ethanolic hf concentration results in different. Electrochemical Etching Silicon.

From www.researchgate.net

(PDF) Porous silicon nanowires fabricated by electrochemical and laser Electrochemical Etching Silicon Web while conventional electrochemical etching is the most widespread approach used. Web electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Varying the etching time and ethanolic hf concentration results in different surface morphologies, with various degrees of electrolyte access depending on the pore. Web for example, cozzi et al. Web we report. Electrochemical Etching Silicon.

From www.researchgate.net

(PDF) Porous Silicon Formation by Electrochemical Etching Electrochemical Etching Silicon Web for example, cozzi et al. Web while conventional electrochemical etching is the most widespread approach used. Varying the etching time and ethanolic hf concentration results in different surface morphologies, with various degrees of electrolyte access depending on the pore. Web here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by. Web electrochemical etching is. Electrochemical Etching Silicon.

From www.researchgate.net

(PDF) Electrochemical Etching of nType Silicon in Fluoride Solutions Electrochemical Etching Silicon Varying the etching time and ethanolic hf concentration results in different surface morphologies, with various degrees of electrolyte access depending on the pore. Web for example, cozzi et al. Web here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by. Web the proposed model of electrochemical etching of silicon makes it possible to explain many. Electrochemical Etching Silicon.

From www.researchgate.net

(a) Schematic illustration of the electrochemical etching approach to Electrochemical Etching Silicon Reported silicon electrochemical etching (ece), which shows an etching rate faster than the dry etch. Web we report the fabrication of nanoporous silicon (npsi) electrodes via electrochemical etching to form a porous si layer with controllable thickness and pore size. Web electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Web the proposed. Electrochemical Etching Silicon.

From www.researchgate.net

(PDF) Fabrication of Porous Silicon Microstructures using Electrochemical Etching Silicon Web the proposed model of electrochemical etching of silicon makes it possible to explain many of the. Web while conventional electrochemical etching is the most widespread approach used. Web electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Web we report the fabrication of nanoporous silicon (npsi) electrodes via electrochemical etching to form. Electrochemical Etching Silicon.

From www.researchgate.net

(PDF) Metalassisted electrochemical etching of silicon Electrochemical Etching Silicon Reported silicon electrochemical etching (ece), which shows an etching rate faster than the dry etch. Web electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Web here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by. Web we report the fabrication of nanoporous silicon (npsi) electrodes via electrochemical. Electrochemical Etching Silicon.

From www.researchgate.net

The electrochemical etching system. Download Scientific Diagram Electrochemical Etching Silicon Web electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Reported silicon electrochemical etching (ece), which shows an etching rate faster than the dry etch. Web for example, cozzi et al. Web here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by. Web the proposed model of electrochemical. Electrochemical Etching Silicon.

From www.researchgate.net

The electrochemical etching cell setup a schematic diagram b real photo Electrochemical Etching Silicon Web while conventional electrochemical etching is the most widespread approach used. Reported silicon electrochemical etching (ece), which shows an etching rate faster than the dry etch. Web the proposed model of electrochemical etching of silicon makes it possible to explain many of the. Web here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by. Varying. Electrochemical Etching Silicon.